By: Kyle Carlton, PG, Senior Geologist

Our client alleviated the site owner’s concerns of driving away customers during remediation construction by proposing and utilizing Directional Technologies and horizontal remediation well installation from an off-site location.

Directional Technologies installed horizontal injection wells, which enabled in-situ chemical oxidation (ISCO) injection with zero interruption to business and customer traffic. Site remediation activities were conducted directly beneath the feet of undisturbed customers. This is how our client saved the gasoline station owners an estimated $8,000 per day during remedial construction –

Introduction

A petroleum impacted corner gasoline station required in-situ chemical oxidation (ISCO) injection remediation for residual contamination in soil and groundwater. But two major challenges faced the environmental consultants:

- How to access the plume beneath the active gasoline dispensers and canopy

- How to minimize site intrusion and business interruption

The solution: horizontal injection wells installed from an off-site location.

Background

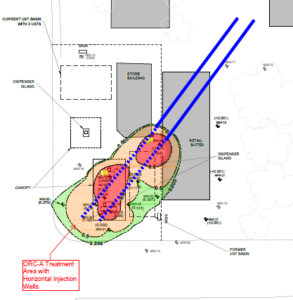

Two past releases of unleaded gasoline from the former underground storage tanks contributed to several areas of soil and groundwater contamination beneath the site. Previous remedial actions included underground storage tank (UST) removal, vertical ISCO injection, and dual phase extraction. A remaining hot spot beneath the dispenser islands and canopy proved to be a difficult area to access with traditional vertical drilling and injection methods.

Approach

To access the impacted area and minimize site disturbance and business interruption, two horizontal injection wells were installed. The entry location for the horizontal wells was established on the vacant property to the north of the site. The borings were advanced to a target depth of 21 feet below ground surface (bgs) in the weathered bedrock zone where the remaining contamination concentrations were highest. The horizontal wells safely traversed beneath an occupied retail building to the target injection locations in the vicinity of the former UST bed and active dispenser islands.The horizontal injection wells were approximately 200 feet in total length with 90 feet of injection screen in each horizontal well. Horizontal wells were constructed of 3-inch diameter schedule 80 PVC with customized, machine cut slotting for the injection of the Regenesis® ISCO product PetroClenze™.

Results

The horizontal injection wells were successfully installed through the weathered bedrock zone at 21 feet bgs. Reinforced grout/bentonite seals around the riser portion of the horizontal well casing were necessary to prevent daylighting of injected fluids. During initial injection testing, the horizontal wells performed at flow-rates of approximately 45 gallons per minute (gpm) with 10 to 13 pounds per square inch (psi) of pressure. Regenesis Remediation Services (RRS) injected PetroCleanze™ in June 2018. Initial remedial results showed favorable declination in concentrations of petroleum constituents in groundwater.

The successful installation and application of horizontal remediation wells at this site further demonstrates the major advantages HRWs have brought to hundreds of environmental sites across the country.

Directional Technologies is proud to have worked alongside Regenesis for successful implementation of this project.