Authors: Gaby Atik, PE – FPM Remediations, Inc., Dave Forse, CPG – FPM Remediations, Inc., and Kyle Carlton, PG, Senior Geologist – Directional Technologies

The Challenge posed to the consultant: Expedite remediation of subsurface petroleum plumes within a complex geological setting at a Department of Defense (DOD) facility, while minimizing site disruptions. Traditional remedial methods such as dig and haul, or large grids of vertical sparge points could not be implemented as these methods were considered to be excessively intrusive to site operations.

The Solution: FPM Remediations, Inc. provided the DOD a remedial design which maximized oxygen delivery using horizontal biosparge wells. FPM’s design combined their vertical biosparging experience with their understanding of horizontal well capabilities from past projects with Directional Technologies. The success of this project resulted in the design and implementation of similar horizontal biosparging systems at other DOD sites across the country.

Background/Objectives: Soil and groundwater at the DOD facility was impacted from at least two documented jet fuel releases and other site activities and required active remediation of four target areas at the base. Unconsolidated sediments consisting primarily of silty sands with areas of gravel and sand mixture with gravels underlain by glacial till ranged in thicknesses from 20 feet to more than 60 feet, providing a porous media for migration of petroleum LNAPL and dissolved constituents in groundwater. Previous remedial efforts including vertical bio-venting and source removal provided partial remediation. Biosparging was selected as the most cost-effective method to remediate the residual impacted areas within the desired time-frame.

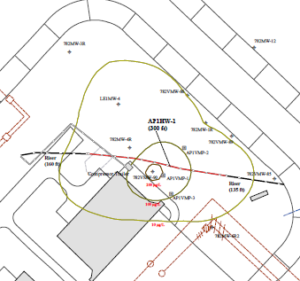

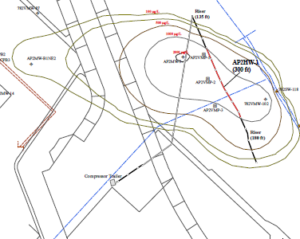

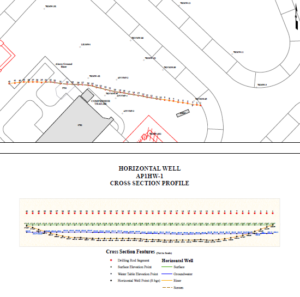

Approach/Activities: To maximize oxygen distribution without impacting site redevelopment, horizontal biosparge wells were designed. Five horizontal biosparge wells with 200 feet to 300 feet of screen were installed with horizontal directional drilling methods at target depths ranging from 24 feet below land surface (bls) to 39 feet bls. The horizontal wells were constructed with 4-inch diameter HDPE casing with customized, software designed slotting for desired air flow and distribution. Ambient air was supplied to the horizontal wells via 25-horsepower rotary claw blowers capable of at least 150 to 225 cubic feet per minute.

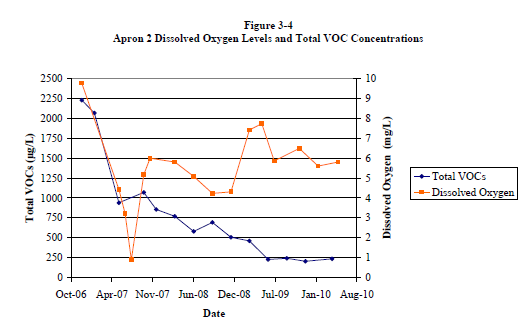

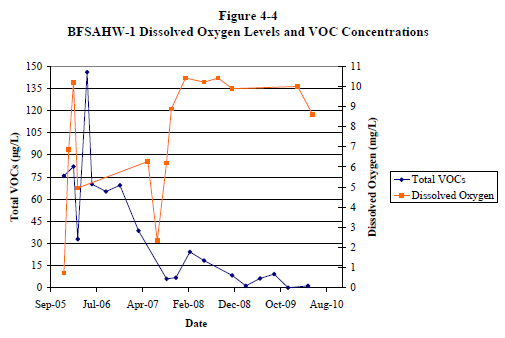

Results/Lessons Learned: The effectiveness of the biosparging system in remediating the petroleum related contamination at the site was indicated by comparing the dissolved oxygen (DO) levels and groundwater and soil gas results to the baseline measurements and results. An increase in DO enhanced aerobic degradation of the petroleum related contamination. As a result of the aerobic degradation, soil gas measurements indicated decreased O2 and increased CO2 measurements. Subsequent groundwater sampling data and biosparging measurements indicate that biodegradation occurred at monitoring locations at least 120 feet from the horizontal wells. Within biosparging areas, decreased depth to water and increased DO measurements were recorded.

Within 3 years of operation of the horizontal biosparge system, groundwater sampling results indicated no volatile organic compound (VOC) concentrations above the regulatory Groundwater Standards.